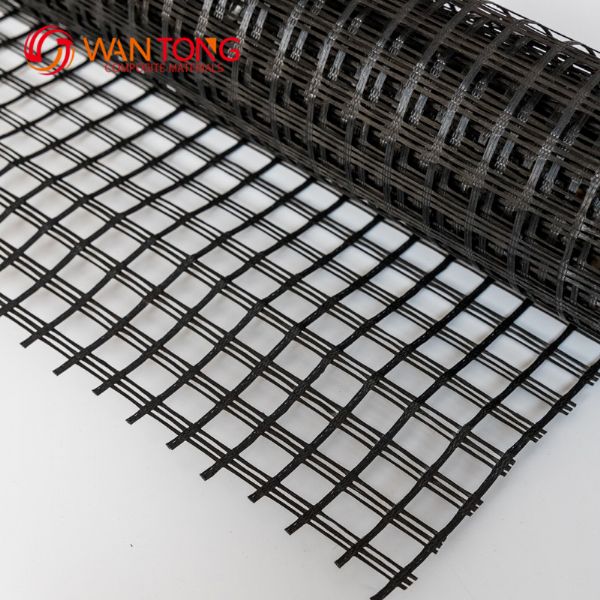

Difference between polyester grid and glass fiber grid

Polyester grating is made of polyester fiber. The warp knitted directional structure is adopted, and the warp and weft yarns in the fabric are not bent with each other. The intersection is bound with high-strength fiber filaments to form a firm junction, giving full play to its mechanical properties. The warp knitted polyester geogrid has high tensile strength, small extension force, large tear resistance strength, small vertical and horizontal strength difference, UV aging resistance, wear resistance, corrosion resistance, light weight, and strong locking force with soil or gravel, It plays a significant role in enhancing the shear resistance of soil and improving the integrity and load capacity of soil.

Main applications

(a) Soft subgrade used for various high-grade roads and railways to strengthen and isolate different soil base materials

(b) It is used for strengthening and stabilizing the bank and embankment slope

(c) Strengthen and stabilize various foundations

(d) Definition of geogrid used for strengthening road and bridge: two-dimensional grid or three-dimensional grid with a certain height made of polypropylene, polyvinyl chloride and other macromolecular polymers through thermoplastic or molding is called geogrid when used as civil engineering.

Glass fiber grid (EGA) is the abbreviation of glass fiber geogrid. The reinforced alkali free glass fiber yarn is used to weave the base material with the advanced warp knitting machine abroad, and the warp knitting oriented structure is used to improve its mechanical properties, so that it has good tensile strength, tear resistance and creep resistance, and is coated with modified asphalt. It follows the principle of similarity and compatibility, highlights its composite performance with asphalt mixture, fully protects the glass fiber base material, improves the wear resistance and shear resistance of the base material, so that it can be used to strengthen the pavement, resist the occurrence of road diseases such as cracks and ruts, and end the problem that asphalt pavement is difficult to strengthen.

Product use

1. The old asphalt concrete pavement shall be reinforced to strengthen the asphalt surface to prevent and cure diseases.

2. Cement concrete pavement shall be reconstructed into composite pavement to resist reflection cracks caused by plate shrinkage.

3. Road expansion and reconstruction project, to prevent cracks caused by new old junction and uneven settlement.

4. The reinforcement treatment of soft soil foundation is conducive to the water separation and consolidation of soft soil, effectively resists settlement, evenly distributes stress, and enhances the overall strength of the subgrade.

5. The semi rigid base course of the new road will produce shrinkage cracks, and the reinforcement will prevent the pavement cracks caused by the reflection of the foundation cracks

| Previous:Usage of Wantong Weeding Cloth | Next:Usage of Wantong Weeding Cloth |

Chinese

Chinese English

English